Invented in 1970’s, water-assisted injection molding (WAIM) is one of the special injection molding methods beyond traditional methods. The concept was developed from gas-assisted injection molding (GAIM). Both technologies were derived to reduce resin cost and better product quality. However, WAIM has some benefits over GAIM such as more even wall thickness, shorter cycle time, lower medium cost, etc.

Although water-assisted injection molding is efficient in reducing material cost and improving product quality, there are still many challenges to overcome. In addition to extra cost, the control of process conditions is also not easy. Some usual defects are fingering effect, blow-through, surface glossy, hesitation mark, switchover mark, and fiber exposure. Since the process is so complex, it may take a significant number of trials to meet the product quality.

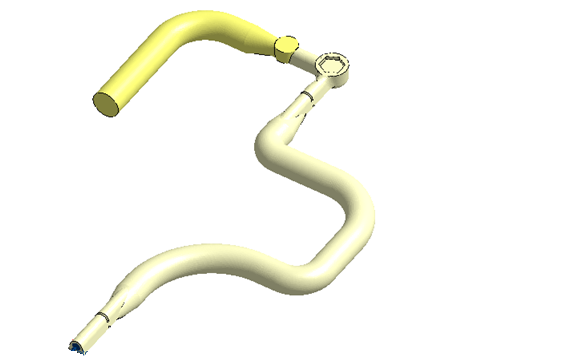

Fig. 1 Â A tube case with overflow region in yellow (left) Â Water and melt front (right)

With Moldex3D’s WAIM module, it provides an effective way for design changes. By predicting flow penetration behavior in three dimensions, the potential problems can be diagnosed prior to mold making stage which can help save developing time and cost. For more information about WAIM, please refer to the conference paper  “Water-Assisted Injection Molding: Validation of 3D Simulations by Experimental Data†or visit our Solution Add-on page for more in-depth features.

Butyl Sheet Production Line,Rubber Tube Extruder,Butyl Roofing Tape,Self Adhesive Butyl Extruder

Hebei Shuangda Rubber & Plastic Machinery Co., Ltd. , https://www.shuangdarubber.com