Millie Lin, Engineer at Technical Support Division, CoreTech System (Moldex3D)

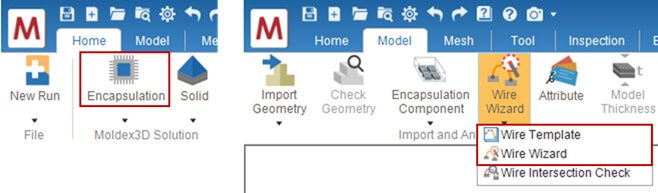

In the IC packaging industry, wire bonding is a technology that uses micron-level metal wires to connect a chip to a lead frame or substrate, allowing electronic signals to be transmitted between the chip and circuits. Moldex3D IC Packaging supports wire sweep analysis, helping users validate wire designs and diagnose potential issues during the manufacturing process. In Moldex3D Studio 2024, Wire wizard and Wire Template functions are added to assist users in importing tiny wire components during the pre-processing stage, speeding up wire design and creation.

Users can use Wire Wizard to apply templates to 2D curves or non-closed curves. After the parameters are set, wire components can be created. In addition, users can manage their template information using Wire Template.

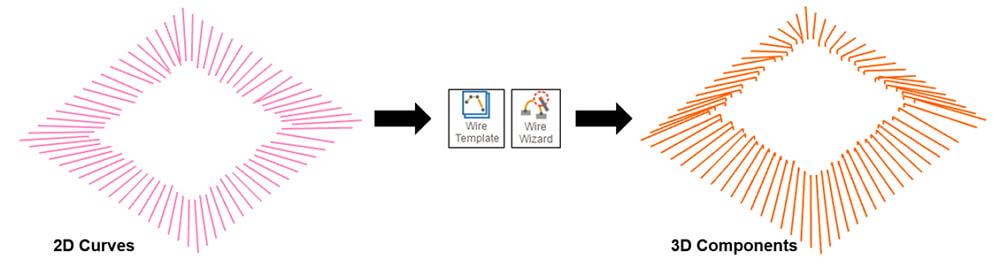

The following demonstrates how to generate 3D wire components from 2D curves using Wire Wizard and Wire Template:

Step 1. Prepare a model

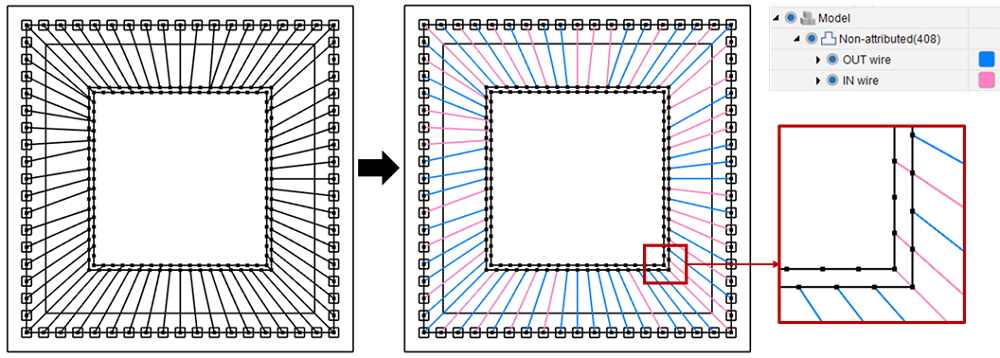

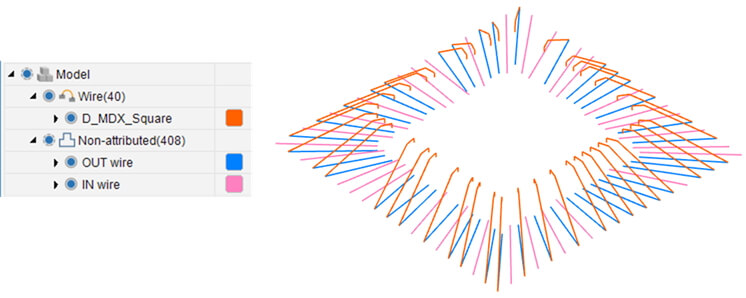

Using 2D curves, classify the curve groups by the connection. As shown below, the blue color represents wires connected to the outside of the box, while the pink color represents wires connected to the inside of the box.

Step 2. Wire attribute setting

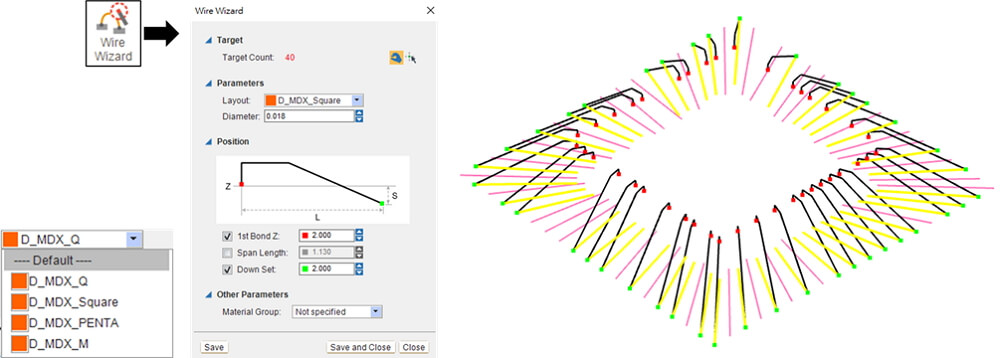

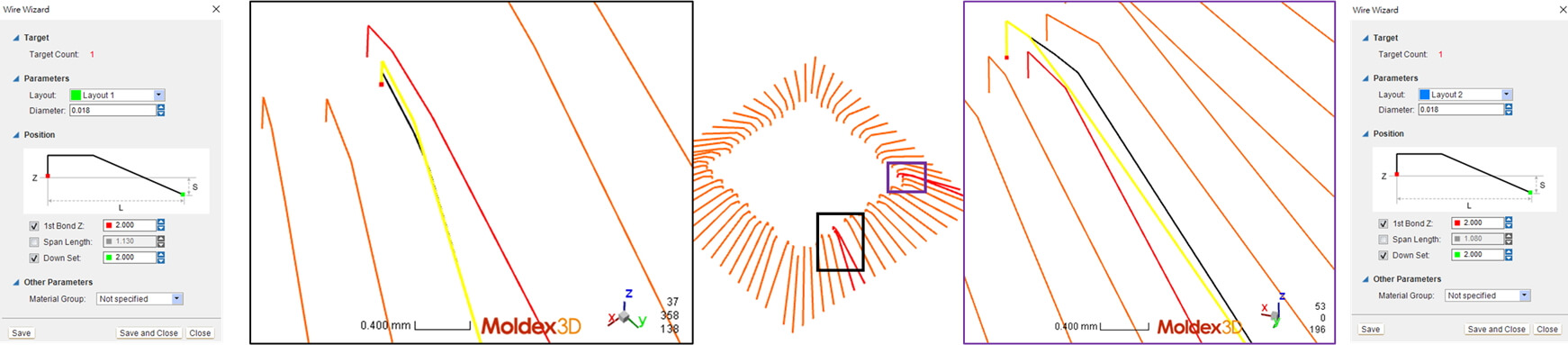

Click Wire Wizard, select the blue curves, and set Layout and Diameter of the wires. There are four default templates in Studio. Also, templates can be created by Wire Template if needed. In this case, the second type (D_MDX_Square) is selected. Next, set the Position, where three parameters are configured: 1st Bond Z, Span Length, and Down Set.

After the setting is finished, click Save, and the orange wire components are generated, while the original blue curves would remain in the original 2D layout.

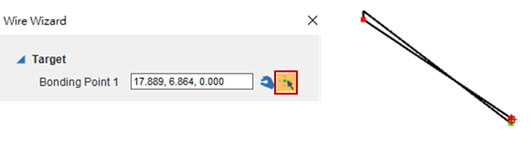

Note: In addition to creating wires by selecting curves, users can also create wires by select the two endpoints of curves.

Â

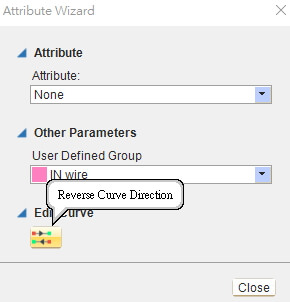

Note: The starting point of wire is set at the beginning of the 2D curve. If the direction is incorrect, users can double-click or right-click and select “Edit Attribute†to reverse the curve.

Â

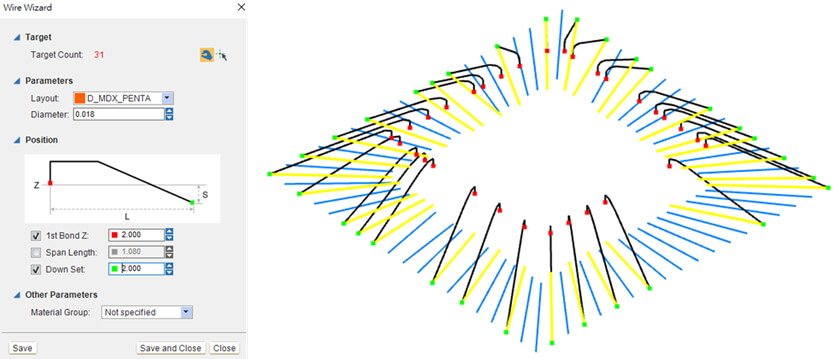

Next, select the pink curves and choose the third type (D_MDX_PENTA). After the parameter settings are finished, click Save and Close.

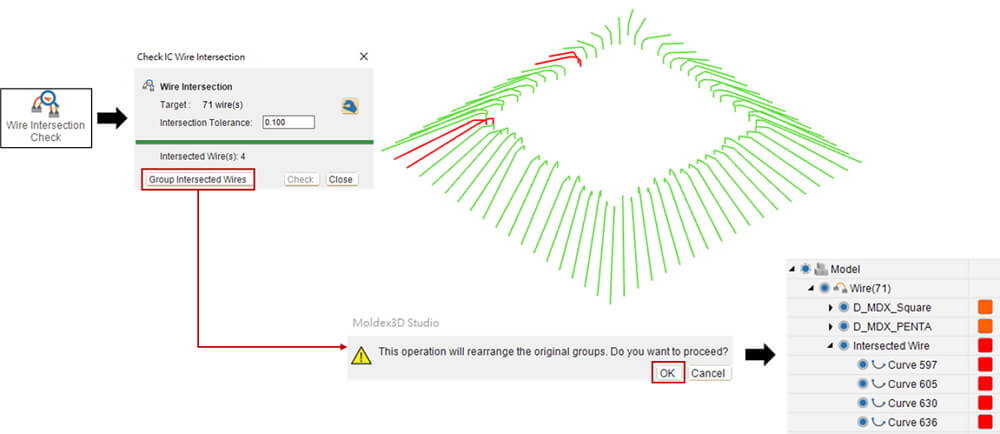

Step 3. Check wire intersection

After the wire components are established, click Wire Intersection Check. There are four intersecting wires, and it is necessary to modify the designs. Click Group Intersected Wires to mark the intersecting wires for easy modification in the subsequent steps.

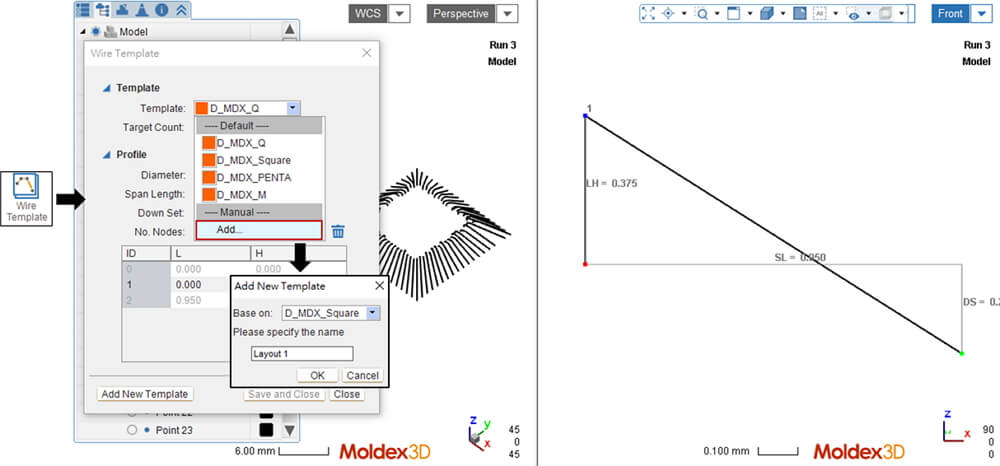

Step 4. Add a wire template

Click Wire Template, and the screen is divided into left and right windows automatically. The left window shows the model, while the right window displays the current wire template design. As shown below, add a new template based on template D_MDX_Square named “Layout 1.†Click OK.

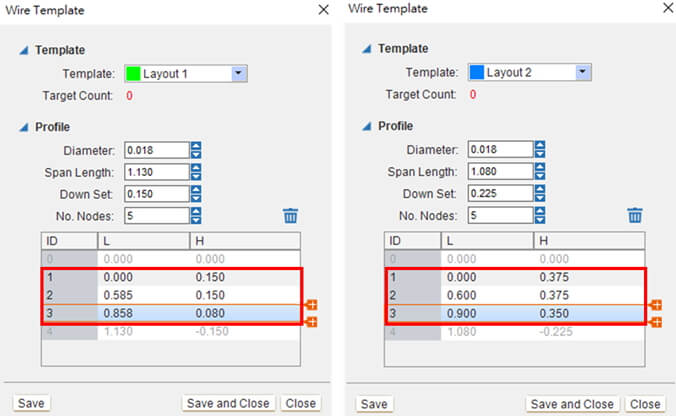

Edit the profile of Layout 1. Change number of nodes to 5 and modify the positions of each node. Then, using the same procedure, add another template based on template D_MDX_PENTA and named “Layout 2.†Click Save and Close to complete the step.

Note: Wire Template does not support Undo/Redo.

Â

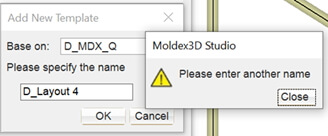

Note: The default template names begin with “D_â€, while for user-defined templates, the software limits the template names begins with “D_â€.

Step 5. Apply new wire templates

Double-click the intersecting wires users want to modify. Apply the newly created template, set the parameters, and then check wire intersection. If intersections still exist, modify the newly created template again until number of wire intersection is reduced to 0.

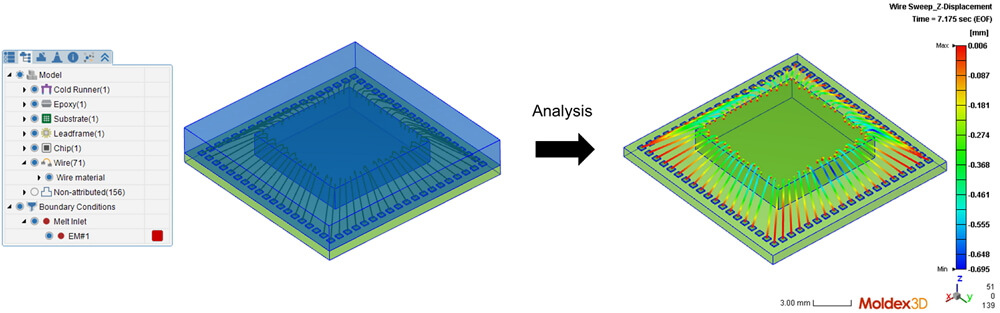

Step 6. Complete pre-process and post-process settings

After the wires are created, the components such as chip, EMC, runner, and lead frame are set sequentially and then mesh is generated. Next, set material, process condition, analysis sequence, and computation parameters. After the analysis is completed, users can view the results of wire sweep analysis.

Vitamin C Ethyl Ether,Ascorbic Acid,Ethyl Ascorbic Acid Ether,Ascorbic Acid Powder

JINGJIANG HENGTONG BIO-ENGINEERING CO.,LTD , https://www.jjhtbio.com