Current well-developed computer-aided engineering technology of mold filling simulation can help users predict potential product defects prior to actual mold production.  It facilitates efficient manufacturing process and high-quality products, and further reduces trial-and-error costs.  In order to provide more accurate simulation results and reliable analysis data for product and mold designs, the fully coupled process simulation capability in Moldex3D R15 is now available. In this analysis calculation, the simulation data in every time-step program solver can be delivered, bringing optimal analysis accuracy.  The differences between conventional and fully coupled process simulation will be interpreted below.

Conventional Analysis Process

Filling, Cooling, Packing and Warp are separate solvers and will run analysis sequentially instead of simultaneously. Â The data transmits among different programs through file communication, which is a one way process. Â For instance, when Filling analysis is proceeding, Cooling analysis has already finished, means Filling and Cooling analysis cannot interact immediately. Â Moreover, the required file and hard disk space will be larger if the communications get more frequent.

Fully coupled Analysis Process

In fully coupled analysis process, the kernels of Filling, Cooling, Packing and Warp are integrated and can run simultaneously, thus, the physical quantities in the mold can affect each other. Â Fully coupled analysis results can be more reliable and consistent to real-world molding. This can also be utilized in predicting heat accumulation areas of complex geometric products.

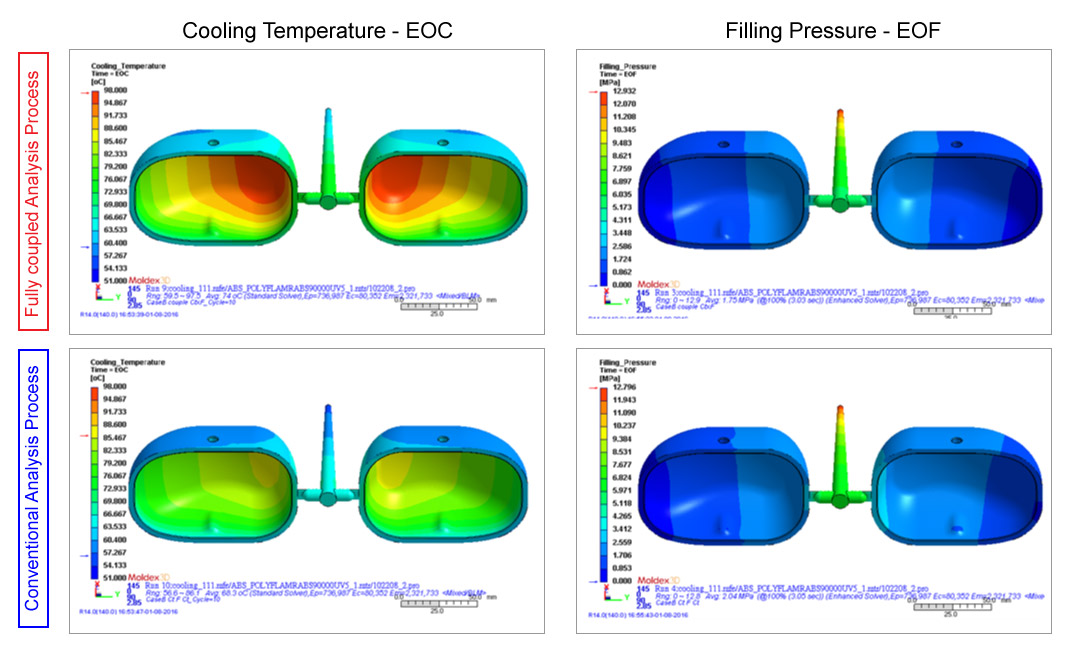

The case in Fig. 1 shows the difference between conventional and fully coupled process simulation.  The shear heating at filling stage will frequently interact with the mold temperature at cooling stage.  The interactions can be considered in fully coupled analysis, so obvious heat accumulation results can be calculated.  This is shown by the difference of pressure analysis results between two simulation types.  The highest temperature in fully coupled analysis is 97.5 ℃.  This is 11.4℃ higher than in conventional analysis (86.1 ℃). Because the pressure data can be delivered more easily, the average internal pressure of the product in fully coupled analysis is 1.75MPa, which is 0.29MPa lower than in conventional analysis (2.04MPa).

Fig. 1Â The comparison of fully coupled and conventional analysis results

Fig. 1Â The comparison of fully coupled and conventional analysis results

As shown in the case above, Moldex3D’s fully coupled analysis brings increased levels of accuracy.  This is especially an ideal option for demanding applications such as automotive parts that require complex geometric designs and optical lenses that made to be high precision ofμm.  Moldex3D fully coupled analysis provides design guidance product engineers require to make informed design decision, cutting significant costs.

Stacker Spreader Beam,Aluminum Spreader Beam,Aluminium Lifting Beam,Telehandler Spreader Bar

VOITH CRANE , https://www.voithcraneasia.com