As the wire strands get smaller in diameter, ensuring the integrity of wire placement has become challenging during the IC packaging process. The common defects include wire sweep, wire breakage and wire cross-over. The common materials for wires are gold, copper, aluminum to name a few.

In order to ensure product quality and improve performance, multiple materials are used in manufacturing. Moldex3D supports wire sweep simulation with multiple wire material definitions.

Wire Material Setting

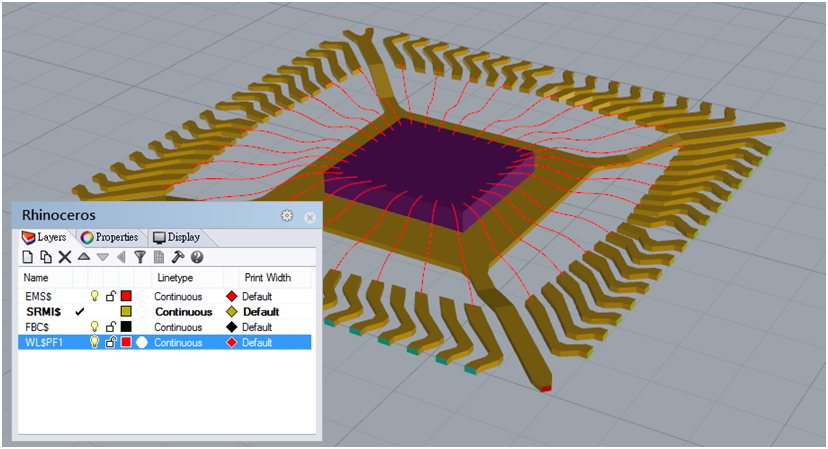

Step 1. In Moldex3D Mesh, users could create solid mesh for IC components and set up the wires. Then, check the Layers: the layer, SRMI$, is the solid model and WL$PF1 is the wire.

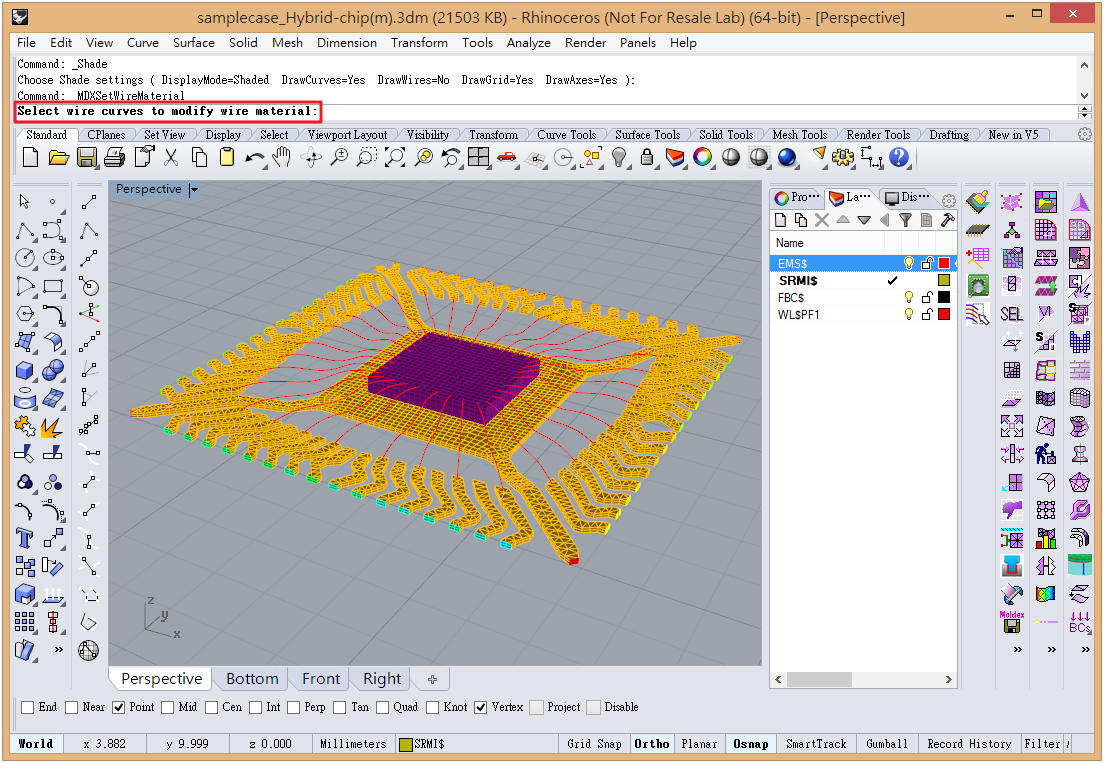

Step 2. Click  Â Wire Material Setting and follow the message in the command prompt.

Wire Material Setting and follow the message in the command prompt.

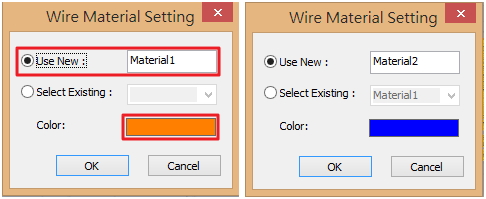

After selecting the wire curves, press Enter. Users could name wire material group and assign the color of it.

Step 3. Export the model with mesh format. Then open Moldex3D Project and create a new project.

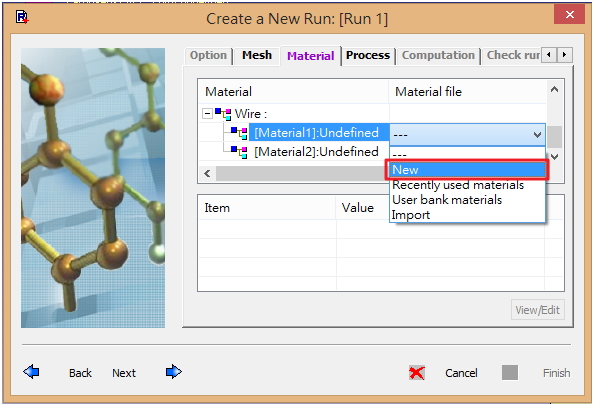

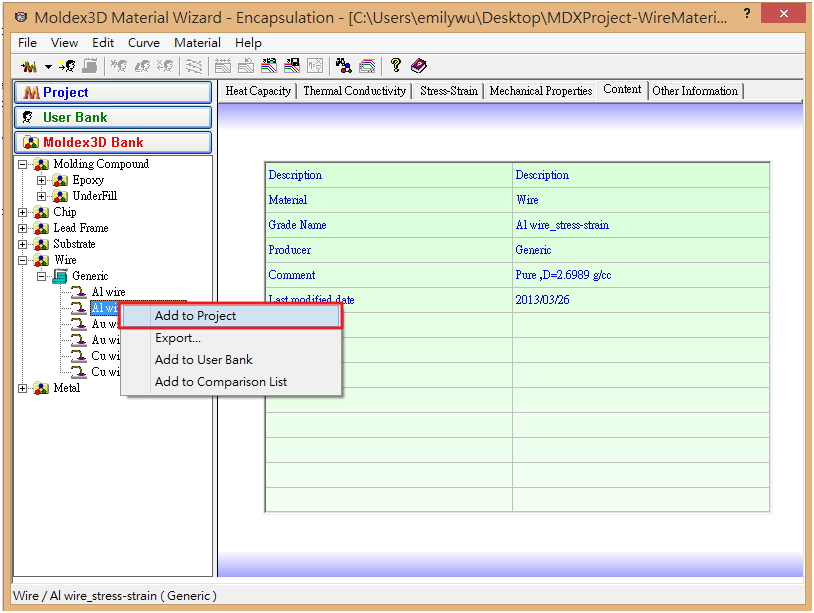

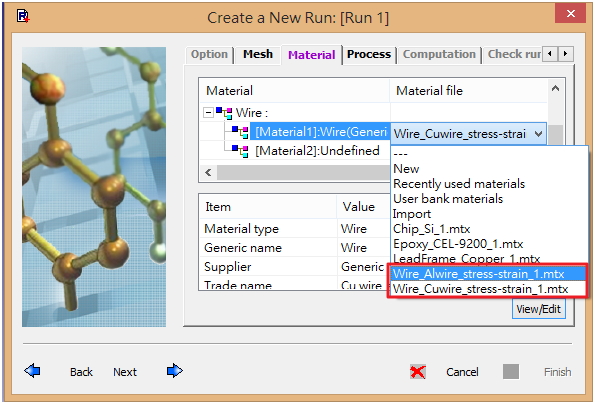

Step 4. Create a new simulation run and assign the material for each wire group. Next, open drop down window and click New to open Moldex3D Material Wizard. Pick the materials and right-click to Add to Project. After choosing all materials you need, close Material Wizard. Users could choose the materials in the drop down window one by one.

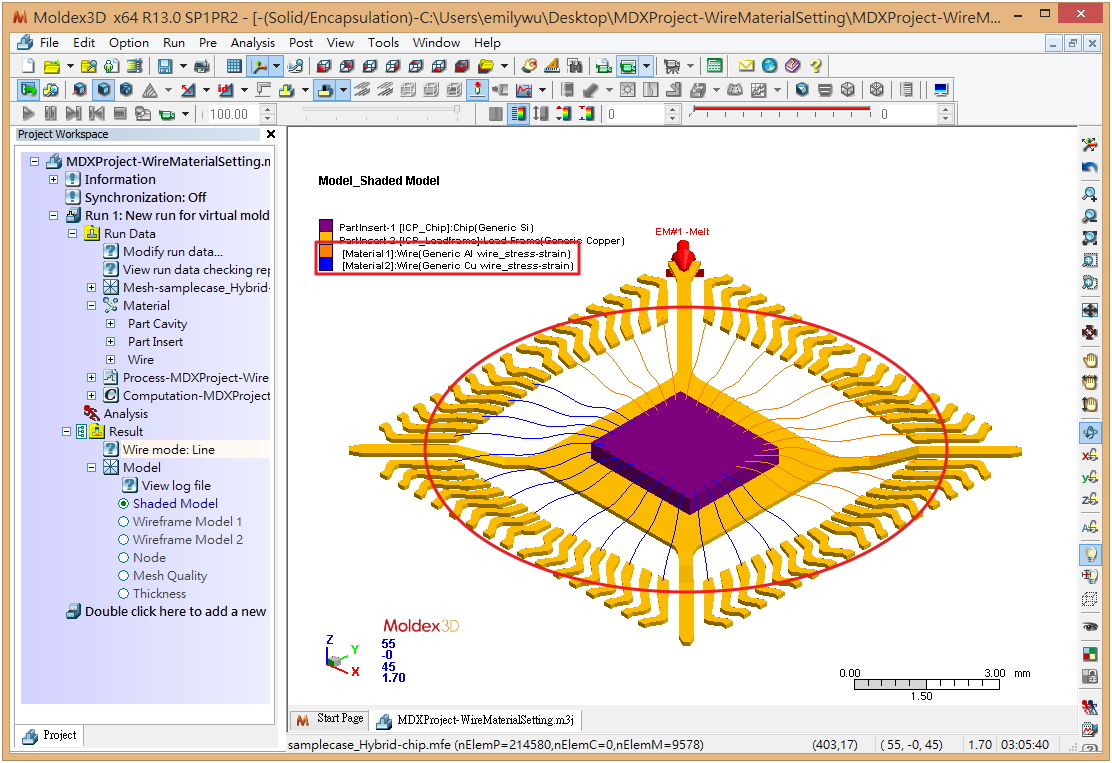

Step 5. Check the model in the display window.

Three-in-one Ceramic Composite Liner

Impact resistant non-stick material,Alumina ceramic composite liner,Flame retardant composite liner,customizable

Hebi Shuanglian Trading Co. , https://www.slwearrubber.com